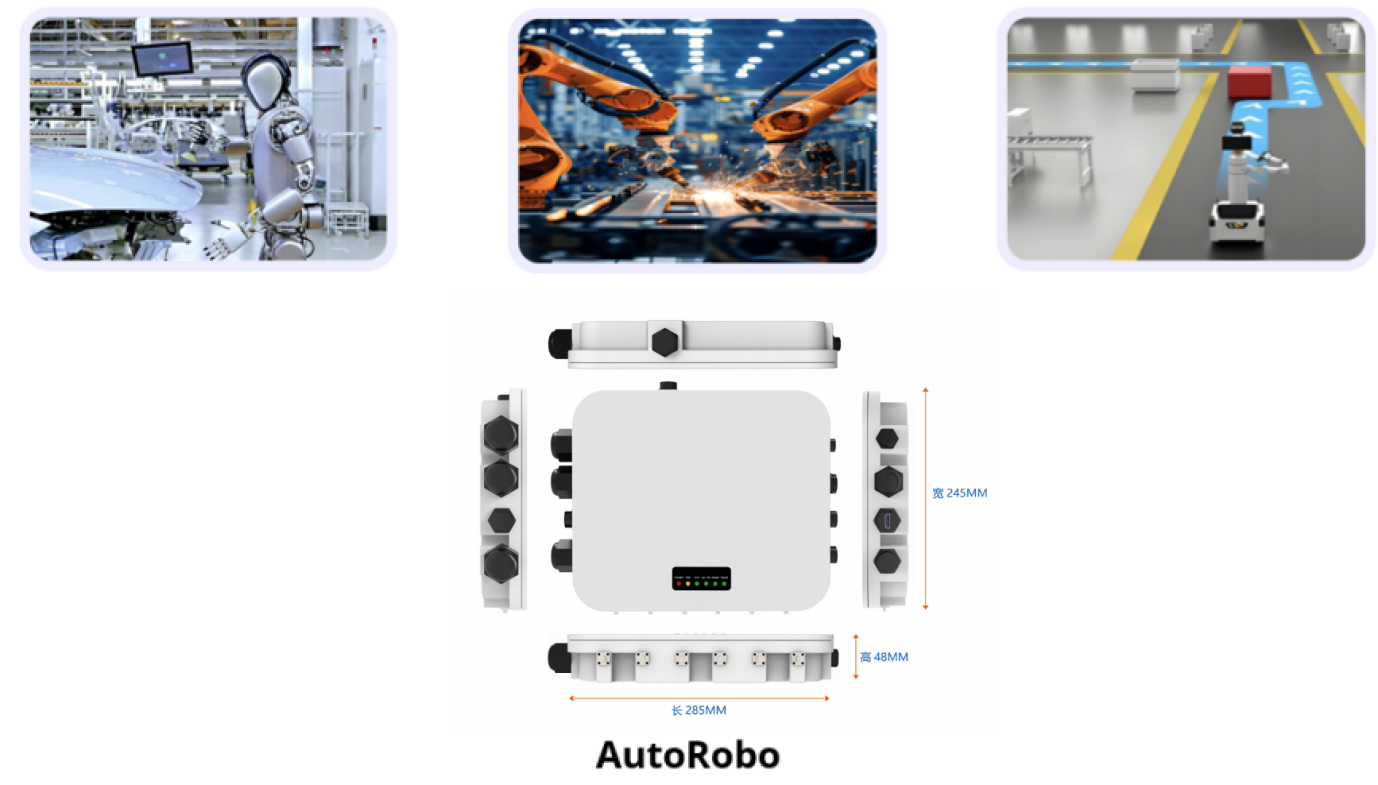

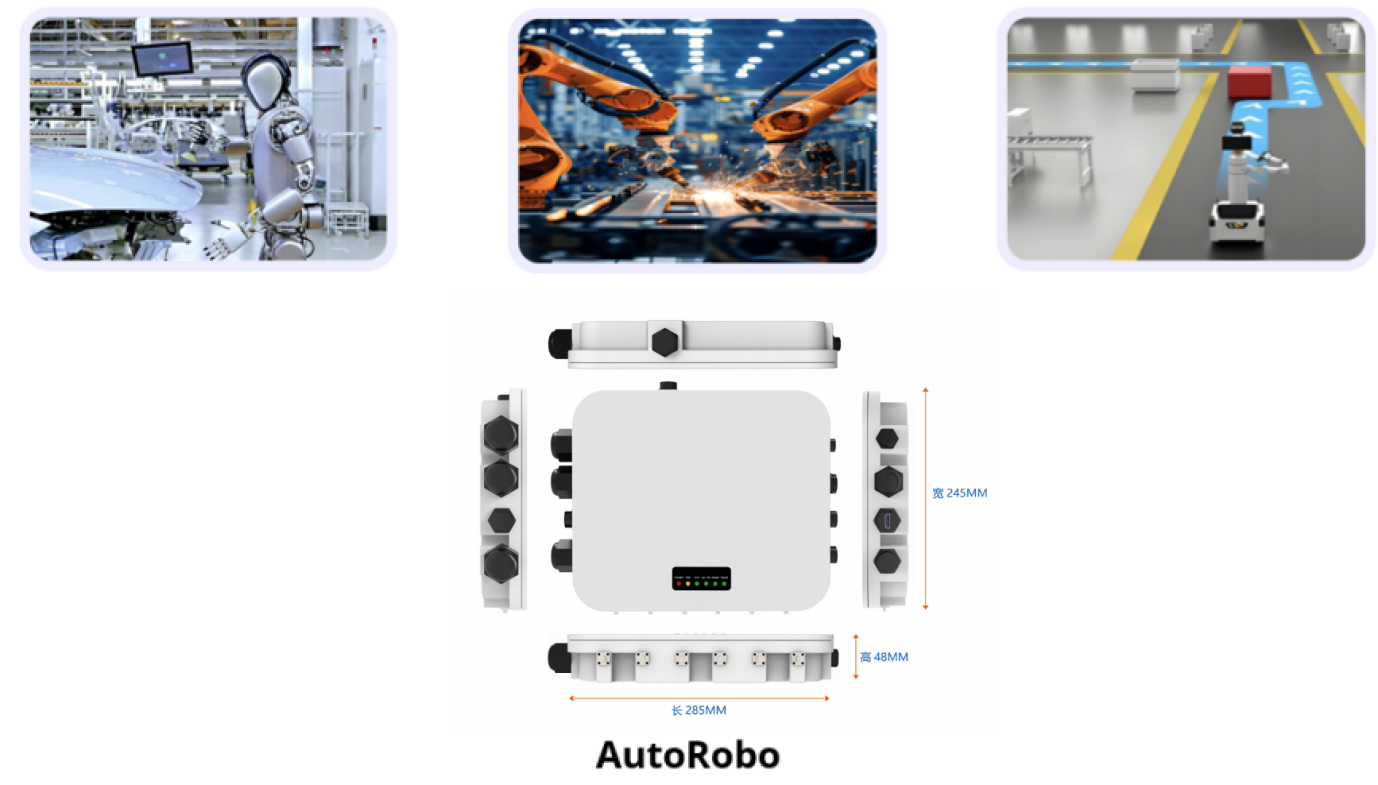

AutoCore 联合贝启科技和瑞芯微,发布AutoRobo国产化机器人平台,打通“原型到量产”最后一公里

All-in-One 软硬件一体化平台,加速机器人从试验样机到商业化部署的落地

[中国· 南京] — [2025年12月10日] — AutoCore联合瑞芯微、贝启科技战略合作,共同推出基于RK3588+RK1828计算卡的AutoRobo国产化机器人平台。该平台深度融合瑞芯微原厂机器人SDK与AutoCore量产级软件栈,打造真正意义上的从芯片,硬件设计,到软件栈的全部国产化,全自主知识产权、可快速规模化量产解决方案,彻底打通从创新原型到商业化部署的“最后一公里”工程瓶颈,帮助企业消除工程瓶颈,显著缩短产品上市周期、提升全生命周期的可靠性与安全性,为企业提供安全可控的机器人量产平台。

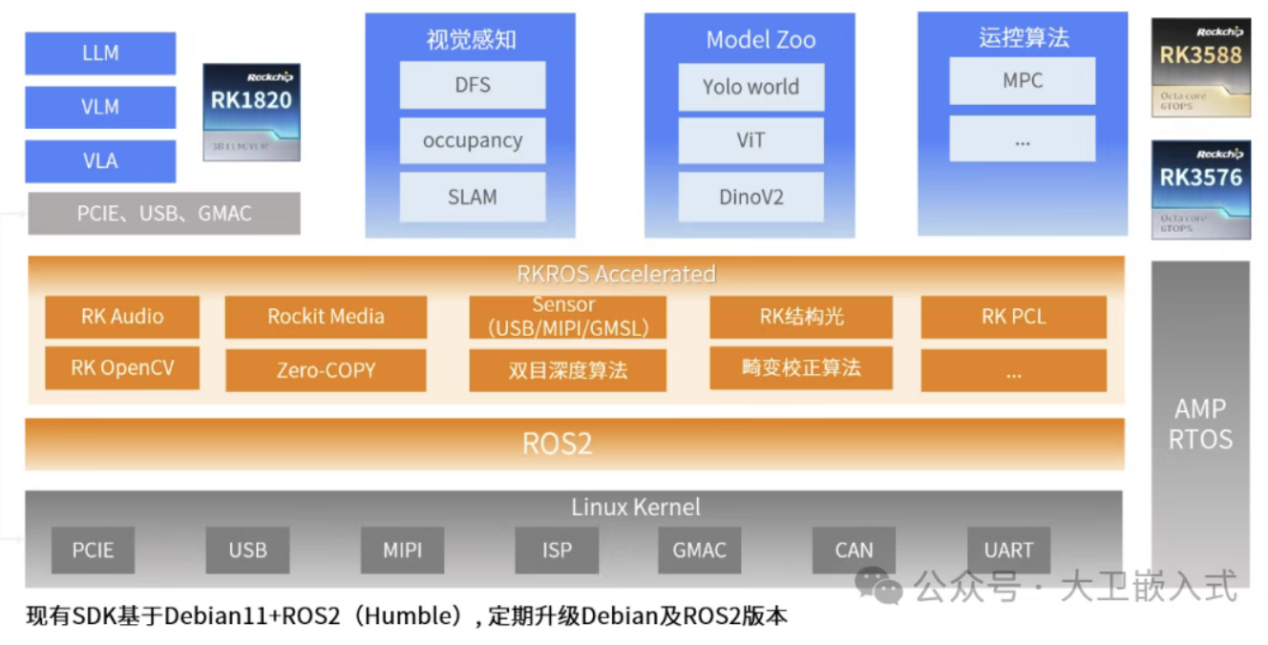

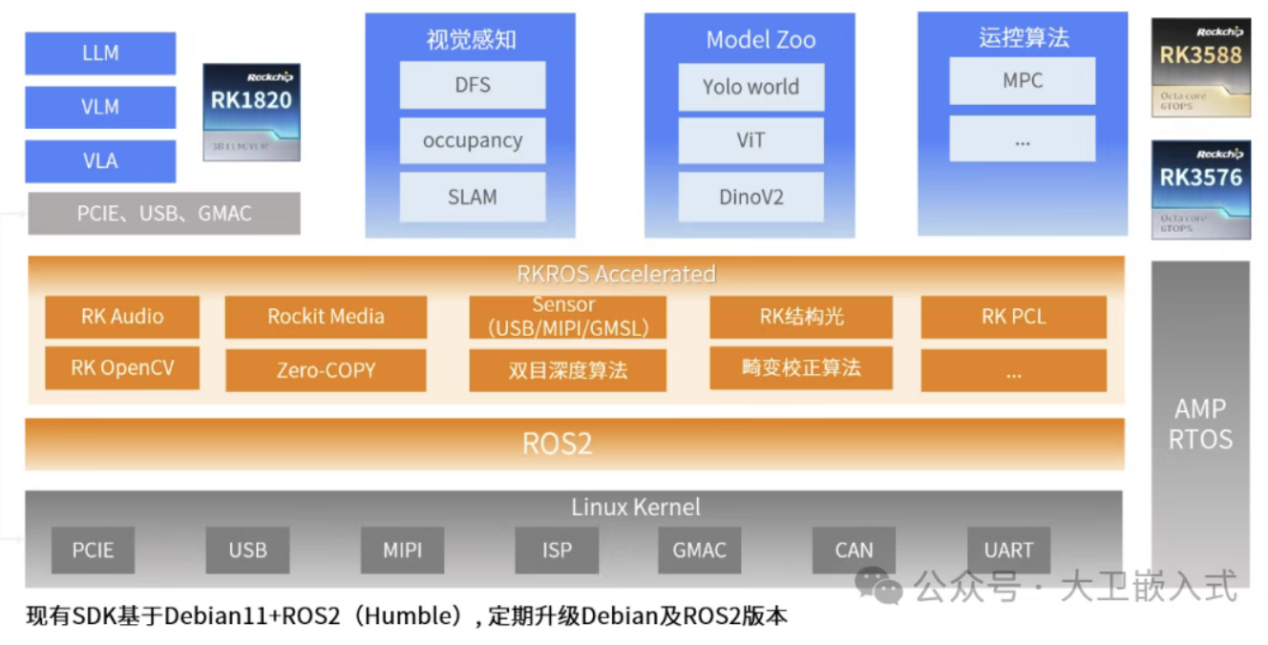

芯片级深度优化,释放国产算力潜能

AutoRobo国产化方案以瑞芯微RK3588旗舰AIoT芯片为核心,构建了一套“主控 + 专用AI协处理器RK1820/1828”的高效异构计算架构,实现从感知、决策到控制的完整闭环,在确定性、集成度和全生命周期管理上的突破性结合:

双引擎算力架构,实现26 TOPS强大性能

- 主芯片RK3588采用8 nm制程,集成4×A76与4×A55 CPU核心,内置6 TOPS NPU,负责运动控制、多传感器融合及高层决策任务。

- 通过PCIe 3.0直连RK1820/RK1828专用AI计算卡,基于RK182X 内置3D堆叠DRAM 带来的高带宽、高算力的优势,支持LLM/VLM等3B/7B参数量大模型在边缘端直接推理,并实现百TPS级别输出性能。同时支持端侧实现VLA/VLN等模型的部署,实现端到端的动作规划,路径规划,避障等任务。

确定性与可靠性的软件基座:AutoCore.OS

- 创新“双内核”架构,告别ROS2量产痛点: AutoRobo基于创新的AutoCore.OS量产级操作系统,采用“双内核”异构计算架构,在单一芯片上实现确定性实时任务(如毫秒级运动控制)与高吞吐非实时任务(如AI视觉、多传感器融合)的完美隔离与高效协同。

- 微秒级控制精度: 实时内核内置AutoCore EtherCAT主站协议,为多轴伺服系统提供微秒级的精确控制。

- 填补原型到量产鸿沟: 在完全兼容ROS2的同时,从根本上解决了开源ROS2方案在复杂网络和应用场景下,存在的通信抖动、不确定性及系统稳定性差等核心问题,为商业化落地提供了可预测、可管理、金石般可靠的基础底座。

- 完整的量产核心能力: 软件栈内置了机器人规模化部署所必需的企业级功能,包括系统级健康管理、运行时管理框架、系统诊断、数据加解密服务、轻量化沙盒(Sandbox)以及可靠的“软件在线升级(OTA)”等。

软硬件深度集成,加速应用开发

贯穿生命周期的可靠性与安全性

- 纵深防御安全体系: 平台提供一整套企业级安全功能,包括支持安全启动、数据加密、端到端访问控制的纵深防御信息安全体系。

- 持续稳定运营保障: 通过持续健康监测与故障自愈机制,保障设备长期稳定运行,满足大规模机器人集群7×24小时严苛的商业现场运行要求。

目标客户与典型应用场景

AutoRobo面向机器人OEM、系统集成商与追求快速产品化的创新团队,是开发下一代自主移动机器人(AMR)、协作机器人、配送机器人与商用服务机器人等产品的理想选择。通过将量产中常见的底层工程难题交给平台,客户能将宝贵的研发资源投入到定义产品、优化算法和提升用户体验等创造核心价值的环节。

三方合作

在本次战略合作中,三方紧密协作,为行业提供了从芯片到软件栈的全栈式、全自主知识产权的机器人量产解决方案:

- 瑞芯微电子:提供核心的AIoT芯片与算力架构(RK3588+RK1828),以及机器人SDK,释放国产算力潜能。

- 贝启科技:发挥其作为瑞芯微合作战略伙伴的优势,提供专业的硬件定制化服务和系统集成,确保硬件平台的可靠性。

- AutoCore:提供量产级AutoCore.OS操作系统和AutoRobo软件协议栈,彻底解决开源方案的量产痛点,确保整体机器人系统的高确定性、可靠性与安全性。

三方合力,共同打通了机器人从创新原型到商业化规模化量产的“最后一公里”。

关于AutoCore

AutoCore 是领先的智能出行与机器人平台解决方案提供商,专注于为产业提供可量产、可扩展的软硬件平台与工程服务,帮助合作伙伴跨越从原型到商业化部署的鸿沟,加速智能时代的到来。

关于贝启科技

贝启科技是一家专注于AI人工智能产品,嵌入式系统软硬件的研发、生产、销售与服务 。是Rockchip的长期合作战略伙伴和方案应用专家,公司可根据客户需求提供硬件定制服务。

关于瑞芯微

瑞芯微电子是一家专注于集成电路设计与研发,全球领先的人工智能物联网(AIoT)处理器芯片企业。 瑞芯微以技术创新为核心,致力于为客户提供多层次、多平台、多场景的专业解决方案,赋能汽车电子、机器视觉、工业应用、教育办公、商业金融、智能家居以及消费电子等多元领域。